FINALLY YOU CAN ACHIEVE ACCURATE COLOR MATCHING FOR YOUR DTF PRINTS - NO MORE GUESSING WITH NIX® AND CADLINK DIGITAL FACTORY or PRORIP DTF!

Jobs where you need to match a specific color happen all the time. Famous brands or logos normally publish CMYK or other color values for their styles, but when you need to color match to a custom color, it can be very difficult to get the perfect color dialed in.

Of course, there's tons of variables in a print workflow, from your machine to your inks to your substrate to your design, but with the NIX® Color Sensor and CADLINK Digital Factory RIP (or PRORIP DTF), you can finally get accurate color output!

The process is easy:

- Start by selecting the job in the queue you want to color match

- Using the job color replacement tool, select the color you want to replace

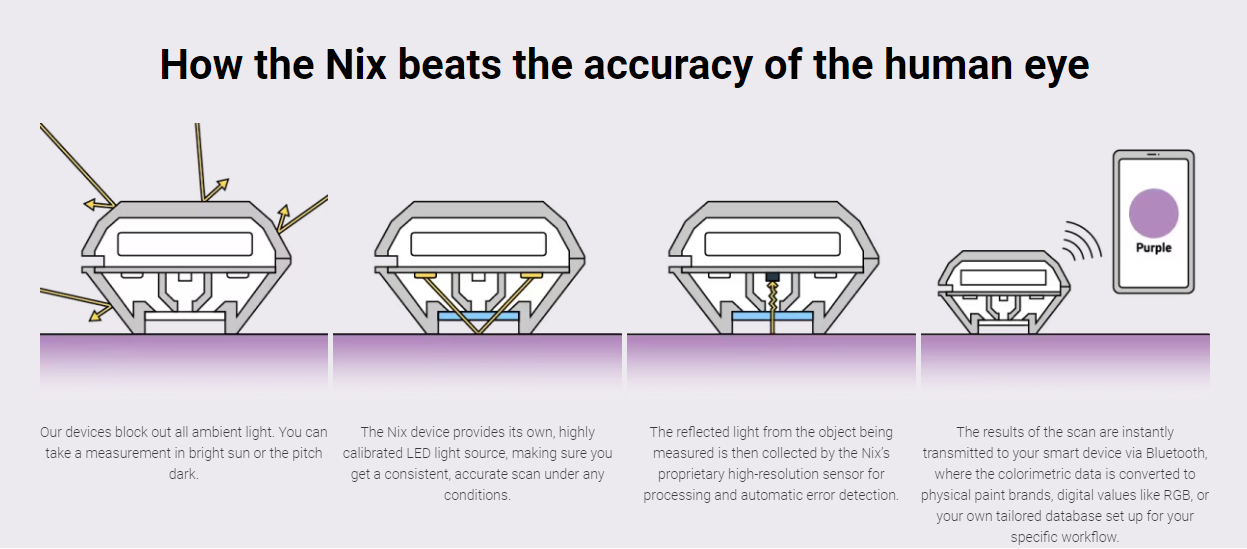

- With the NIX® Color Sensor and your mobile device, scan the color you want to match (the NIX Sensor will yield accurate CIE lab values for you)

- Input the returned CIE lab values into the appropriate fields in CADLINK Digital Factory RIP or PRORIP DTF, click apply, and that's it!

Watch the short video below to see an example of how easy it is to do!

NIX MINI 2 vs. Nix PRO 2:

The NIX Pro 2 has a greater performance in terms of repeatability and interinstrument agreement; and the NIX Pro 2 has improved durability which means it can stand up to more abuse and give the user more confidence that the device will be performing as expected over time.

What you need for successful color matching:

- NIX SENSOR (NIX MINI 2 or NIX PRO 2)

- RIP SOFTWARE (either CADLINK DIGITAL FACTORY RIP or PRORIP DTF RIP)

- ICC PROFILING MODULE FOR CADLINK | PRORIP DTF (works with both CADLINK and PRORIP DTF)